Safer Acrylic Polyol Solutions

Moving toward more sustainable solutions

Arkema provides an extensive selection of binders, including standard solids, high solids, very high solids, and waterborne 2K PU. Our commitment lies in offering more environmentally friendly solutions that prioritize:

- Safety

- Reduced VOC emissions

- Lower carbon footprint

To further advance this commitment, we offer non-isocyanate (NISO) solutions to answer consumers' need for sustainability and encourage safer and greener practices.

Transitioning towards increasingly sustainable solutions

2K Polyurethane SystemsPolyurethane systems have rightfully earned their reputation as a reliable choice for topcoat applications in various industries. Their outstanding performance, durability, chemical resistance, UV resistance, and aesthetic versatility have made them a popular choice for protecting and enhancing surfaces in a wide range of applications. Polyurethane systems constitute approximately 11% of the overall paints and coatings market, predominantly finding application in the protective market and encompassing both heavy-duty and light-duty segments. Solventborne products continue to hold the majority share in this market, accounting for 87% of the total volume. However, there is a notable upsurge in the demand for waterborne alternatives, which is expected to experience a promising annual growth rate of 5 to 10% in the mid-term, subject to regional and segment-specific variations. Opting for high solids and waterborne resins is a viable way to reduce the use of solvents and lower the carbon footprint (in kg CO2eq./kg) of your paint, all while ensuring the paint maintains high-performance durability.(Sources: IRL market research company, European Coatings Journal)

|

|||

|

Standard Solids PU |

High Solids PU |

Very High Solids PU |

Waterborne 2K PU |

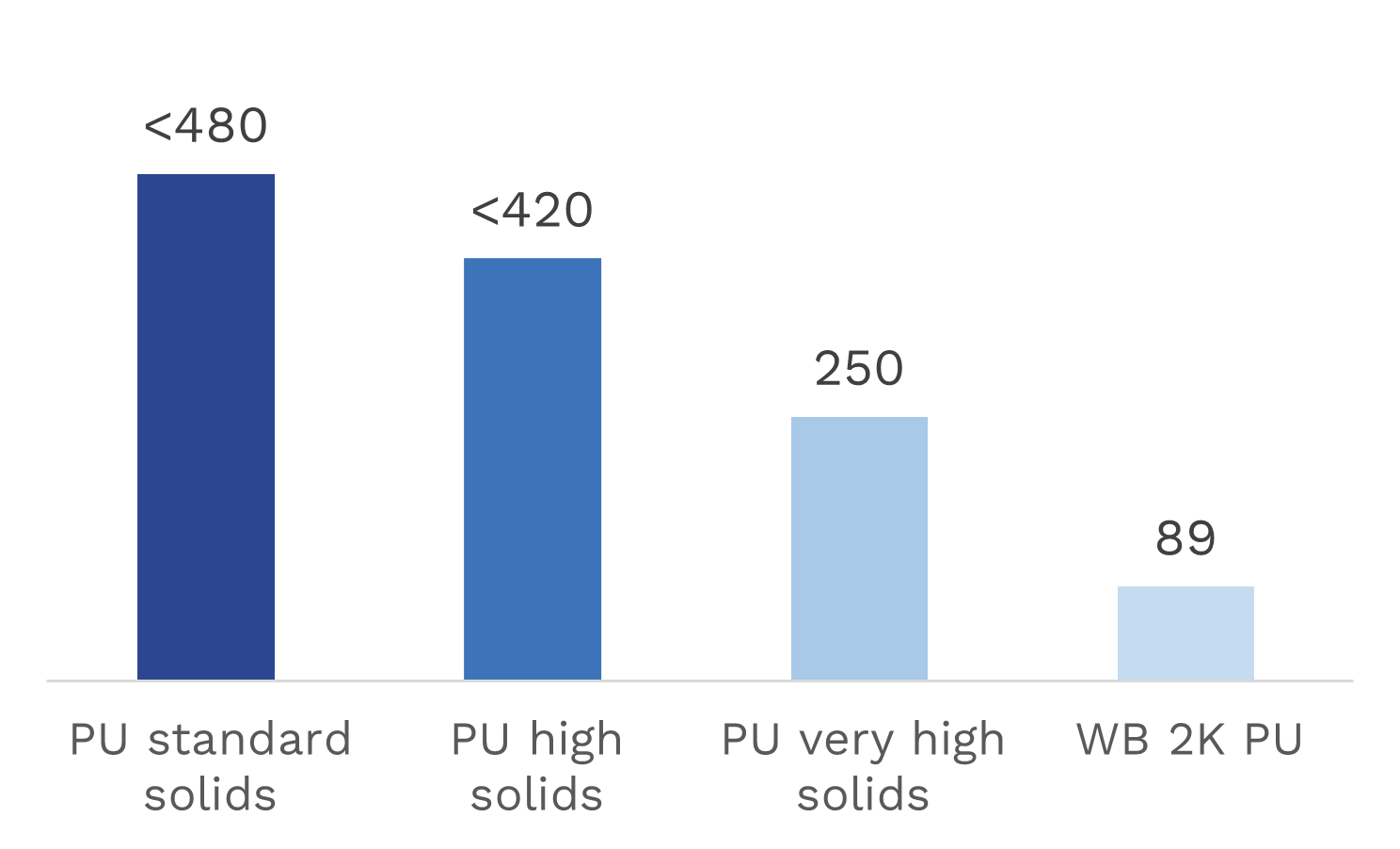

VOC level of 2K PU systems (g/L)

By employing waterborne 2K polyurethane as the binder, the paint achieves a VOC level that is only 1/5th of the amount found in a standard solids PU.

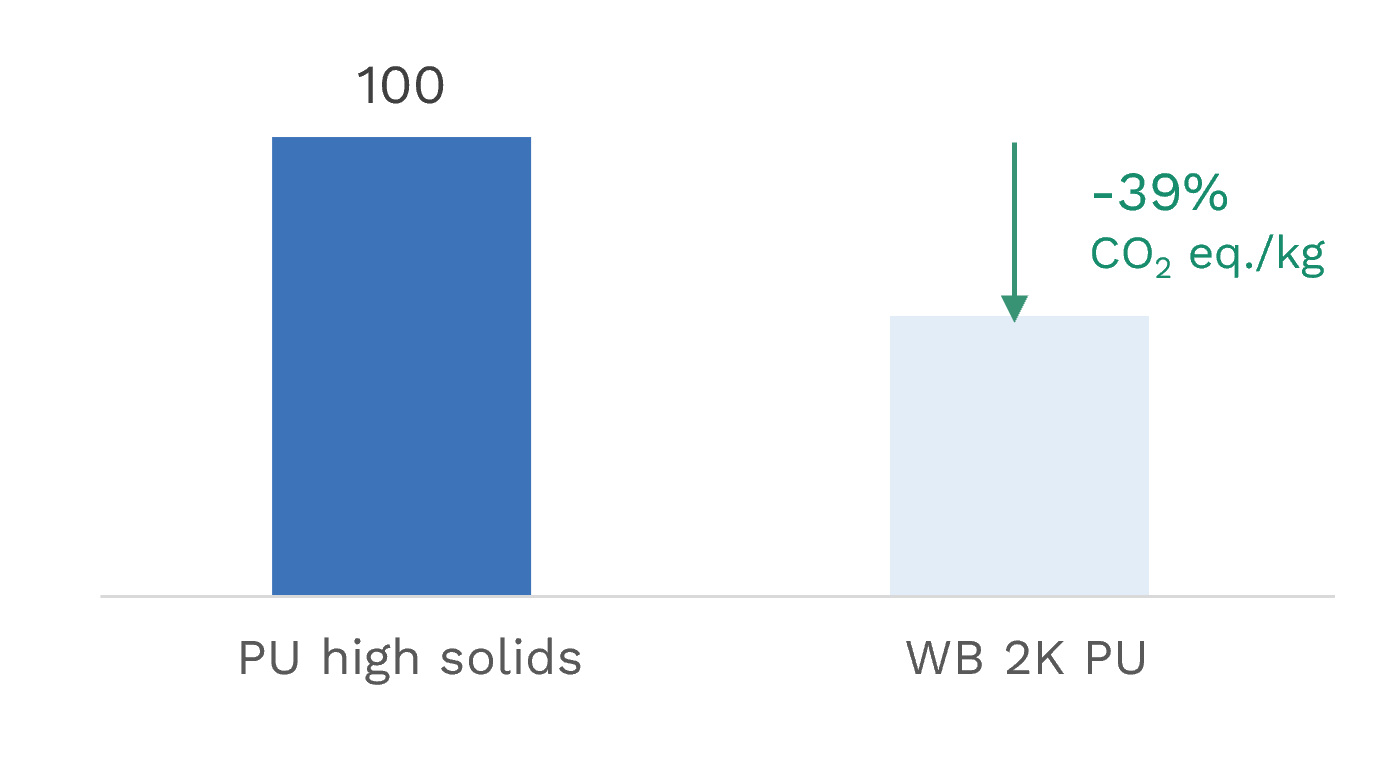

Product carbon footprint cradle-to-gate (kg CO2 eq./kg)

Compared to high solids PU, waterborne 2K polyurethane has a 39% lower carbon footprint cradle-to-gate.

Non-Isocyanate SystemsAnother alternative for safer polyurethane paint involves the development of binders which cure without isocyanates known as sensitizers. These binders are commonly known as Non-isocyanate (NISO) binders and can be used in both standard solids and high solids formulations. Arkema's R&D group is actively working on waterborne 2K NISO solutions, aiming to further reduce the carbon footprint associated with these innovative coatings. Results show that waterborne NISO has a 46% lower carbon footprint cradle-to-gate than common PU high solids binders. This new innovation significantly lowers the use of hazardous materials (isocyanate), reducing VOC emissions and carbon footprint while upholding high performance.Lower VOC Emissions

|

||

|

Standard Solids NISO |

High Solids NISO |

Waterborne 2K NISO |

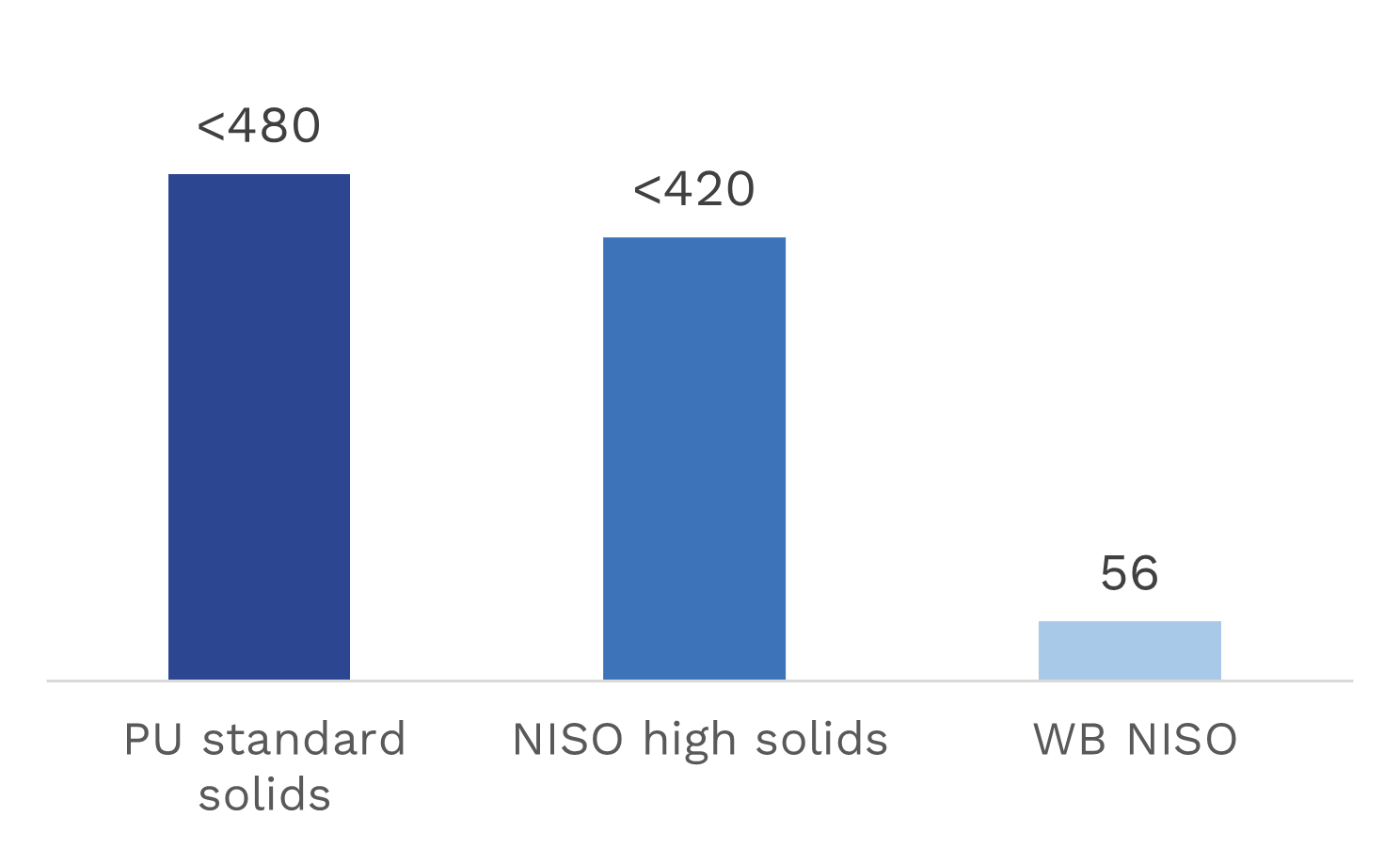

VOC level of Non-isocyanate systems (g/L)

By using SYNAQUA® waterborne NISO as binder, the paint achieves a VOC level of 56 g/L.

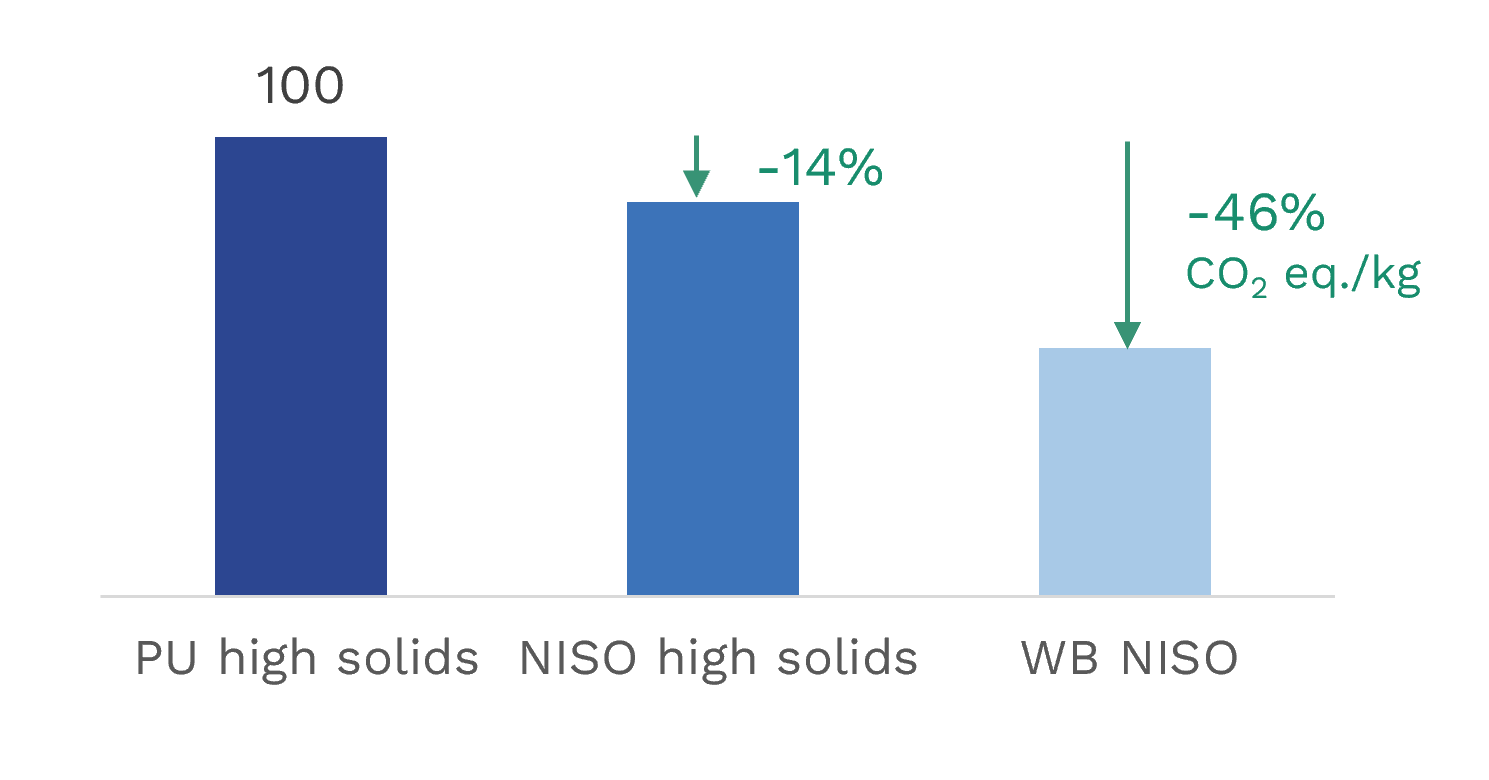

Product carbon footprint cradle-to-gate (kg CO2 eq./kg)

Compared to high solids PU and NISO high solids, SYNAQUA® waterborne NISO has, respectively, 14% and 46% lower carbon footprint cradle-to-gate.

Discover our new Industrial Coatings Brochure

ARKEMA Industrial Coatings Brochure

Download our new Industrial Coatings brochure to find:

- Our full range of binders for industrial applications by chemistry

- Typical characteristics, main application fields & properties

-

Industrial Coatings Brochure (EMEA)