Protective & Marine Coatings

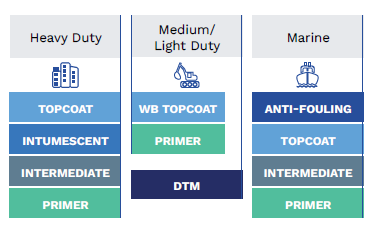

We cover all your high-performance paint systems for Protective & Marine Coatings

The heavy-duty protective coatings market covers a very wide range of product types, suitable for applications for extremes of performance. For example, high performance anticorrosive primers and topcoat systems for marine and offshore environments; or specialized chemical resistance coatings for tank linings; or conventional primers and topcoats for general protective and maintenance work.

Key properties

- Long service life

- Chemical resistance

- Colour stability

- Responsive cure under varying conditions

- Overall cost of the coating

Expertise in transformation towards a more sustainable offer

Sustainability is at the core of our strategic direction to bring continuous new product developments to the market. Our key drivers for innovation integrate long lasting coatings with extreme resistance, safer technologies for the applicators and the environment as well as productivity enhancement and asset protection.

Key drivers for development integrate:

Key drivers for development integrate:

- Elimination of Substances of Concern & Hazardous Air Pollutants: Lower VOC, HAPs free, solvent-free, Non-isocyanate (NISO) paint systems

- Downstream Benefits: Direct-to-metal (DTM) capable, fast cure

- Durability: Long-lasting coatings with improved adhesion, UV durability, chemical and abrasion resistance

- Alternative Feedstocks: Resin based on renewable monomers available. Mass Balance approach (Certificates upon request)

Protective & Marine Coatings key products

| Product | Chemistry | OH (%) | Solid content (%) | Layer | Performance |

|---|---|---|---|---|---|

| Acrylic polyol | 2.1 | 80 | Topcoat DTM |

|

|

| Acrylic polyol | 2.3 | 70 | Topcoat DTM Primer |

|

|

| SYNOCURE® 878 N 60 | Acrylic polyol | 2.7 | 60 | Topcoat Primer |

|

| NISO - Carboxyl acrylic | - | 70 | Topcoat DTM |

|

|

| NISO - Epoxy acrylic | - | 70 | Topcoat |

|

|

| Vinyl acetate emulsion | - | 55 | Intumescent |

|

(1) % of bio-attributed carbon/total organic carbon on the product as supplied. Calculated via Mass Balance approach. Certificate available upon request.

ACCESS TO OUR INDUSTRIAL COATINGS PRODUCTS FINDER

Discover our Protective & Marine Coatings offer

Protective and Marine Coatings Brochure

Download our brand-new PCM brochure to find:- Our product selections for PCM applications by chemistry

- Technical characteristics (VOC levels, UV durability etc.)

Industrial Coatings Brochure

Download our Industrial Coatings Brochure to access:

- Our full range of binders for Industrial applications by chemistry

- Typical characteristics, main applications fields & properties

-

Protective and Marine Coatings Brochure (Global offer)

-

Industrial Coatings Brochure (EMEA)